As a design guru, the software developer delves into logistics service providers' requirements like no other. He is passionate about exchanging information securely and efficiently and thus speeding up the physical logistics process.

Global value chains have made logistics processes increasingly complex. If suppliers, interfaces or transport routes fail, the supply of companies easily comes to a standstill. That's why logisticians and service providers have been working for years to raise resilience to disruptions. Auto-identification technologies such as RFID (Radio Frequency Identification), NFC (Near Field Communication) and UWB (Ultra-Wideband), which communicate via radio, are an important tool for this.

Logistical planning thrives on information. If you know exactly which items you are expecting, where they are currently located and when they are expected to arrive at their destination, you can adjust your production and delivery accordingly. This is a process advantage that requires a closed information chain. Those who want to establish a tightly meshed information chain rely on seamless tracking along all interfaces in the logistics chain. With radio-supported auto-ID technologies such as RFID, users save themselves manual scans and benefit from automatic

Unlike optical systems with one and two-dimensional area codes or shape recognition, the radio data signals are also suitable for undoubted localisation via their frequencies out of sight.

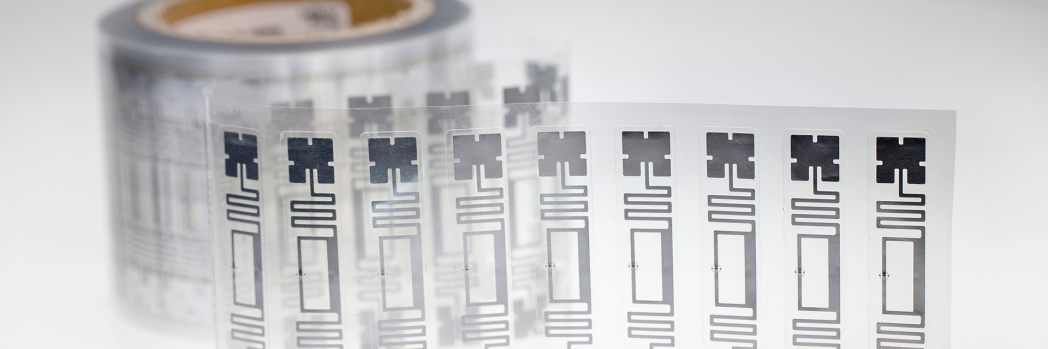

One of the strengths of radio technologies is their enormous speed. They identify goods in seconds without physical or visual contact. In logistics processes, these solutions mean enormous advantages in traceability. In addition to consignments and packages, individual items can also be recognised automatically. This also allows effortless recording of individual work steps. At the same time, RFID technology offers far-reaching advantages over barcodes and QR codes: The tags used can function as independent data storage devices and thus provide information automatically in a decentralised manner. For a smoothly functioning RFID-supported process, freight forwarders and logistics companies need readers with antennas, tags and RFID printers, as well as actively transmitting transponders with microchips, their own power supply and a longer range, depending on the intended use.

Through their ability to store data on the object, RFID tags already document the completion of all tasks in logistics processes parallel to their execution. In this way, they also enable the items to store their processing and transport history, or to provide test reports on quality and origin. They deliver this content contactlessly at physical thresholds in the logistics process and thus intervene in process control. In this way, logistics companies also secure advantages in internal route planning and create flexibility and scalability in their material flow. Through targeted data evaluation, they increase the efficiency of their processes and can better utilise their transport resources.

With auto-identification, the use of RFID technology reduces the number of interfaces required in logistics processes and thus allows for faster material provision. This makes it possible to automate processes that would otherwise require a great deal of manual effort. Including, for example, the incoming goods department with the inspection of the delivered products. As radio tags make it possible to check incoming goods in real time. If it confirms the completeness of all expected articles, it can also independently activate the downstream processes, for example the just-in-sequence assembly of component groups or car bodies in the automotive industry. The data transfer gives production planning the automatic go-ahead for the intended production. Even compared to the most advanced optical identification features such as barcodes, QR codes and data glasses, this is an enormous advantage because no visual contact is required to recognise individual items – for example, the packaging units on a mixed pallet of piece goods. The information is automatically recorded and transmitted by RFID readers at thresholds such as the loading gates. An enormous increase in speed and thus also a driver for significantly higher efficiency.

Stable logistics processes require precision and elasticity, i.e. the ability to spontaneously adapt in real time to all conceivable deviations. Auto-identification technologies such as RFID not only speed up data acquisition and data collection. They also link the information chains much more tightly because, in addition to continuous status recording, they also enable localisation at any time. With this high information density, forwarders and logisticians can proactively modify their transport planning before process errors and shortfalls in the supply of goods occur. This is efficient and also significantly improves the resilience of value chains.